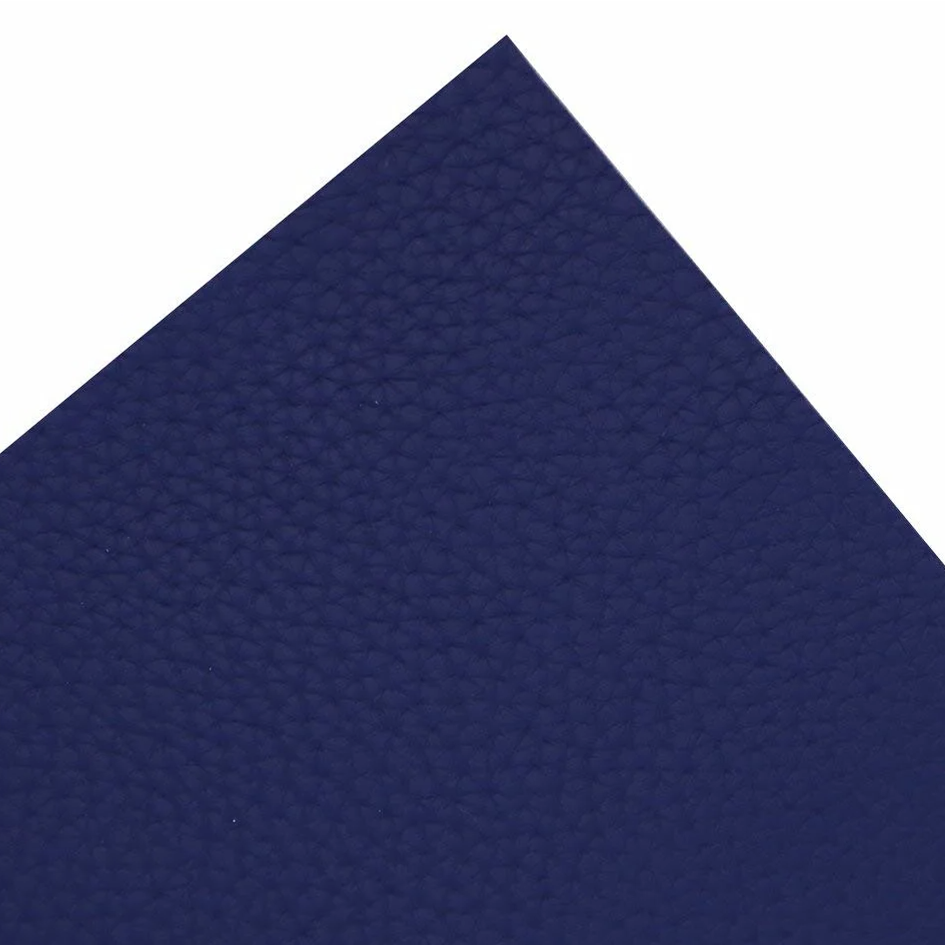

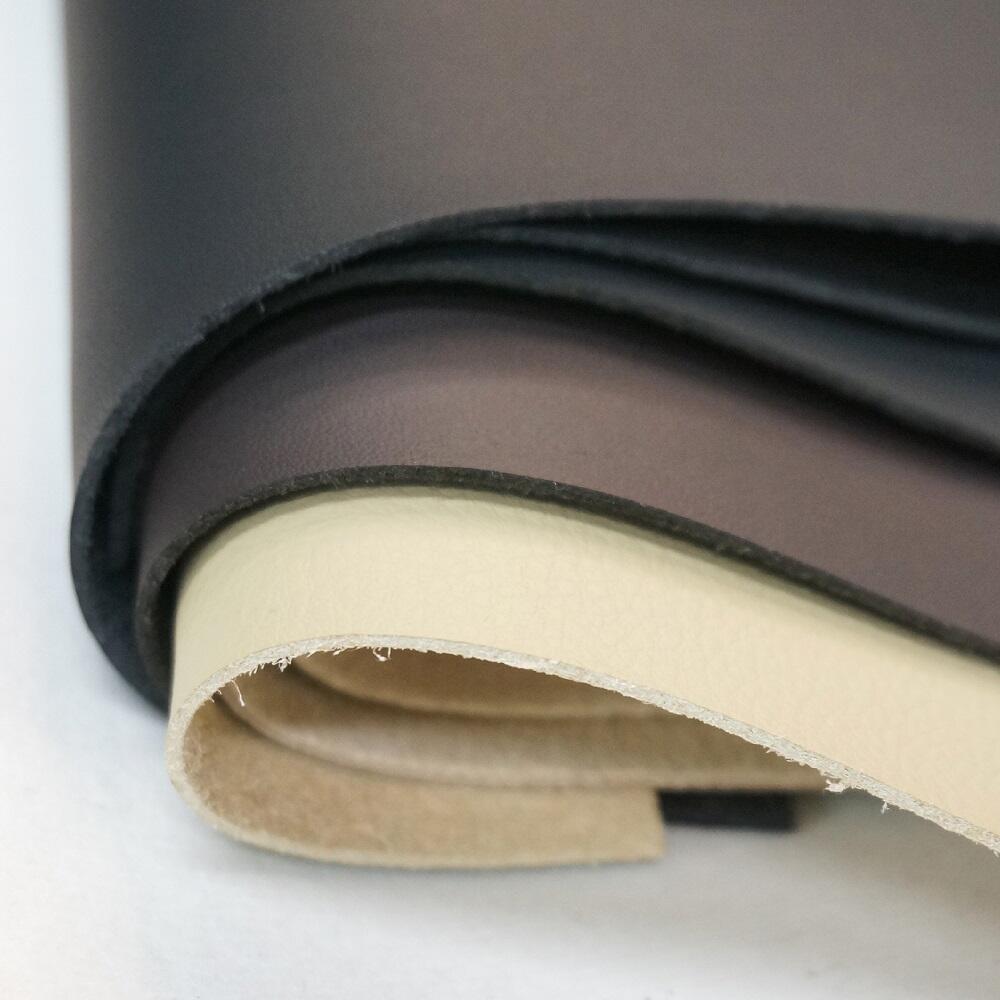

Custom Printing Microfiber Designer Leather Fabric Artificial Synthetic Leather for Handbag Car Furniture Sofa

- Parameter

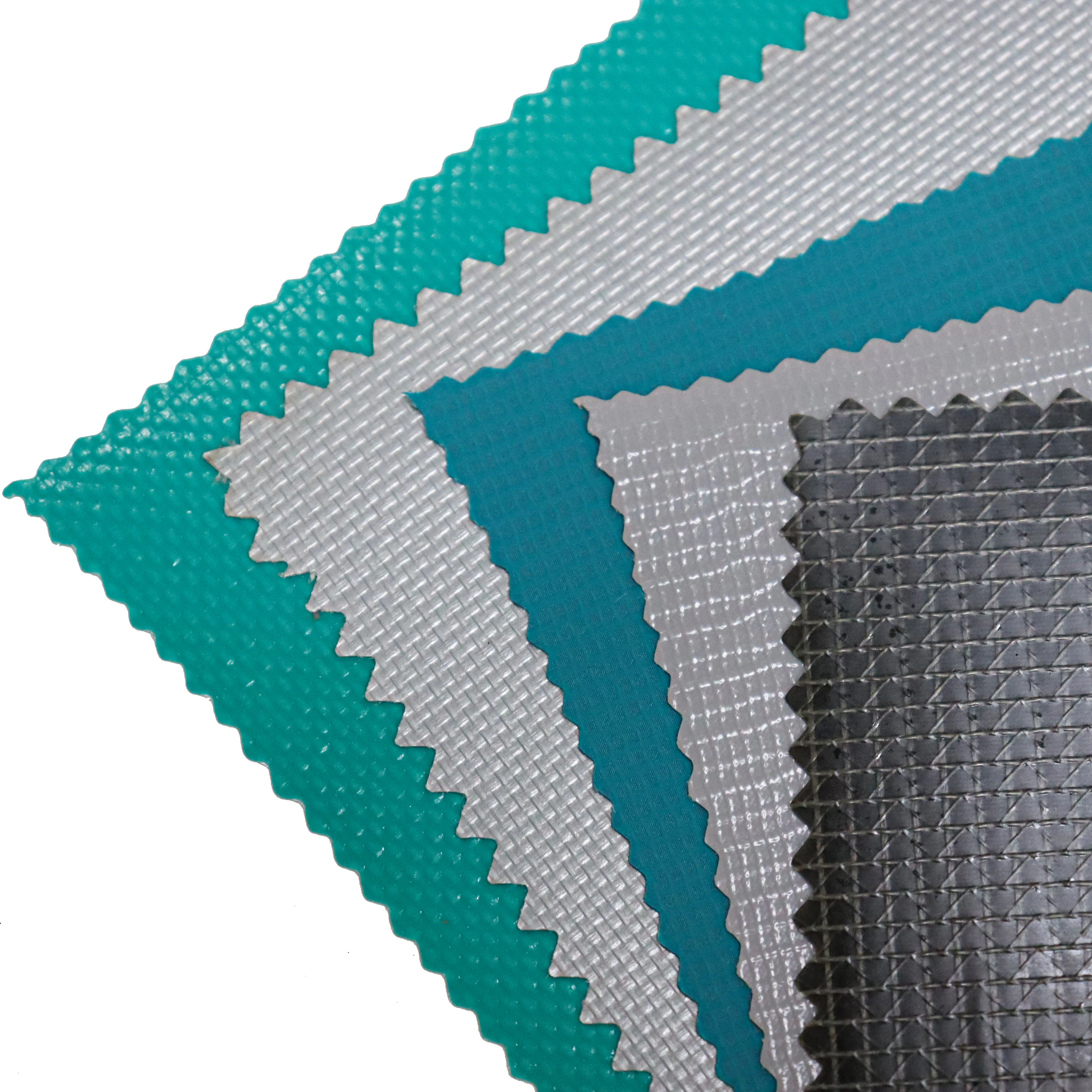

- Related products

- Inquiry

Parameter

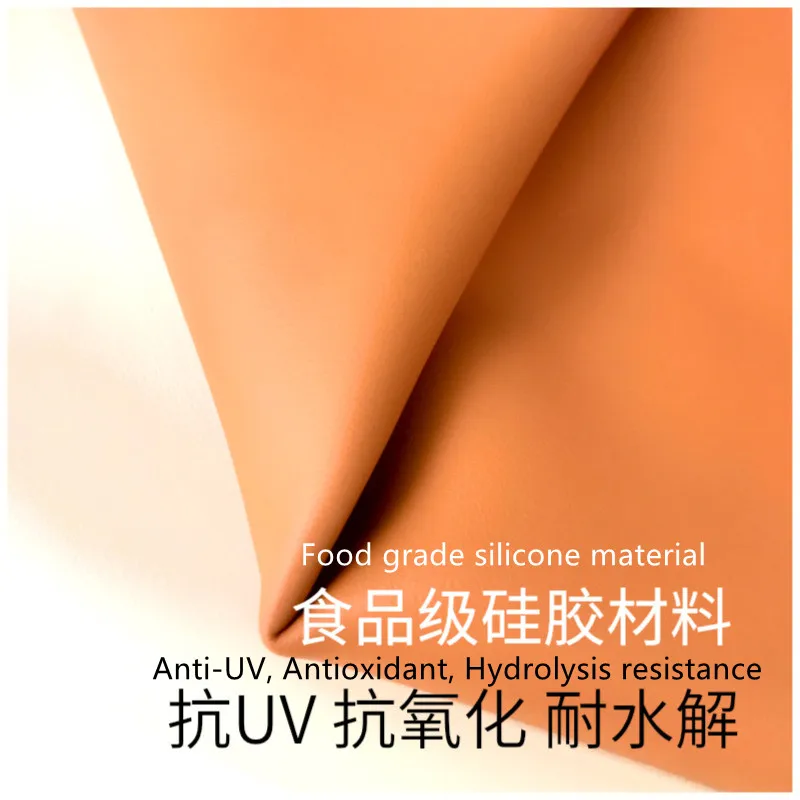

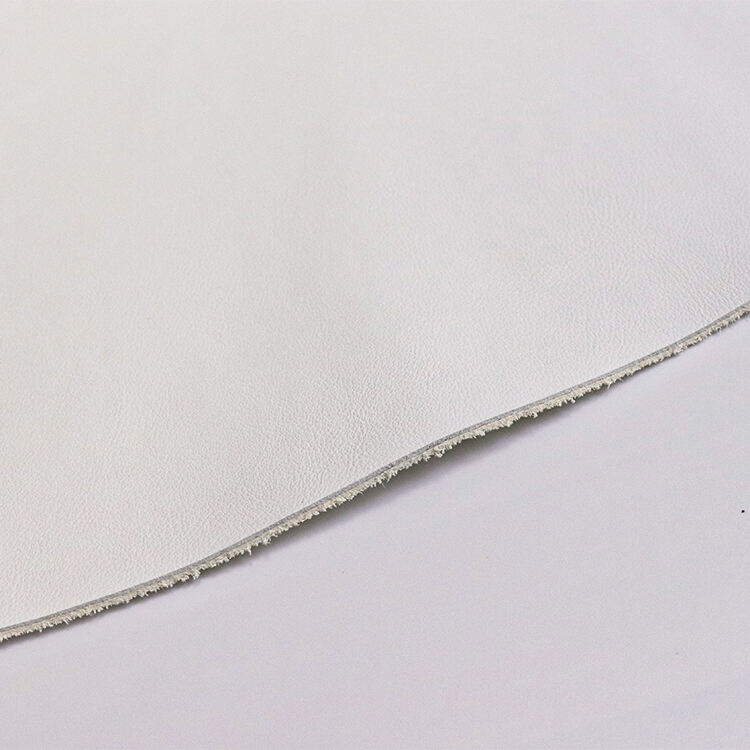

microfiber leather is the highest quality grade synthetic leather (faux leather or PU leather), a high-tech simulation of high-end leather material. Cici Microfiber Leather is simulated the structure of natural leather, using sea-island superfine micro fiber (ultra-fine fiber bundle), and high-grade polyurethane resins as raw materials, using needle punched nonwoven technology of 3D structure, has a lot of similar characters as natural leather, however better physical & chemical performance, has been widely popular around the world.

Feature | Waterproof, Elastic, Anti-Mildew, Abrasion-Resistant |

Place of Origin | Guangdong, China |

Backing Technics | Microfiber |

Pattern | Embossed |

Width | 54/55" |

Thickness | 0.6mm-1.5mm/Customized |

Usage | Shoe/Bag/Notebooks case |

Color | Customized Color |

Backing | Knitted Backing |

MOQ | 1 Meter |

Sample | A4 Sample |

In the ever-evolving landscape of material innovation, the realm of synthetic leather has witnessed a revolutionary stride with the advent of Custom Printing Microfiber Designer Leather Fabric. This cutting-edge marvel has redefined the boundaries of creativity and functionality, offering a versatile solution for a myriad of applications such as handbags, cars, furniture, and sofas. Combining aesthetic appeal with durability, this Artificial Leather variant emerges as a frontrunner in the world of contemporary design and manufacturing.

Unveiling the Essence of Microfiber Designer Leather:

At the core of this remarkable material is microfiber technology, a weaving of ultra-fine synthetic fibers that replicate the luxurious texture of genuine leather. What sets Microfiber Designer Leather apart is its ability to mimic the intricate details, suppleness, and visual allure of natural leather, while simultaneously addressing ethical and environmental concerns associated with traditional leather production.

Custom Printing: A Canvas of Endless Possibilities:

The term 'custom printing' adds an extra layer of allure to this synthetic leather innovation. Manufacturers now have the freedom to imbue their creations with bespoke designs, patterns, and textures, allowing for unparalleled personalization. Whether it's a handbag adorned with intricate motifs, a car interior reflecting the owner's unique style, or furniture and sofas tailored to complement diverse interior aesthetics, the possibilities are truly limitless.

A Greener Alternative:

In an era marked by an increasing awareness of environmental sustainability, the utilization of synthetic leather offers a compelling alternative to traditional animal-derived materials. Custom Printing Microfiber Designer Leather Fabric stands as a testament to the industry's commitment to eco-conscious production methods. By opting for this synthetic variant, consumers contribute to the reduction of environmental impact associated with the leather industry, without compromising on quality or style.

Durability Redefined:

One of the standout features of this synthetic leather is its exceptional durability. Engineered to withstand the rigors of daily use, Microfiber Designer Leather ensures that products crafted from it not only exude elegance but also stand the test of time. From the resilience required in handbags to the endurance demanded by car interiors, furniture, and sofas, this synthetic leather delivers on the promise of longevity.

Handbags: A Symphony of Style and Substance:

In the world of fashion, the handbag is more than a mere accessory; it is a statement of style and individuality. Custom Printing Microfiber Designer Leather Fabric elevates the handbag game by offering designers the freedom to translate their artistic visions onto a material that seamlessly blends luxury with ethics. Imagine a handbag that not only complements your outfit but also reflects your personality through custom-designed patterns and prints.

Cars: A Luxurious Drive:

The automotive industry is no stranger to the transformative power of materials. Microfiber Designer Leather has found its place in car interiors, bringing a touch of opulence without compromising on performance. The custom printing feature allows car manufacturers to create interiors that are not only aesthetically pleasing but also align with the brand's identity. From classic sophistication to modern minimalism, the possibilities for interior customization are boundless.

Furniture and Sofas: Creating Timeless Comfort:

The allure of Microfiber Designer Leather extends to our living spaces, where furniture and sofas play a pivotal role in shaping our daily experiences. The custom printing option allows homeowners and interior designers to curate spaces that resonate with a unique sense of style. The supple texture of this synthetic leather ensures that comfort is not sacrificed in the pursuit of aesthetics, creating a harmonious blend of luxury and coziness.

Conclusion: A Future Envisioned in Microfiber Designer Leather

In the age of innovation, Custom Printing Microfiber Designer Leather Fabric emerges as a beacon of progress, seamlessly marrying elegance with ethical considerations. From handbags that tell a personal story to cars and furniture that embody a brand's ethos, this synthetic leather variant transcends conventional boundaries. As we stride into a future where sustainability and style coalesce, the allure of Microfiber Designer Leather stands as a testament to the industry's commitment to creating a world where elegance knows no compromises.

Faq

1.Q:How about your MOQ ?

A:1meter. If we don't have any in stock or customized materials,MOQ is 500meters to 1000meters per color.

2.Q:How to prove your eco-friendly leather ?

A: We can follow your requirements to reach the following standards:REACH,California Proposition 65,(EU) NO.301/2014,etc.

3. Q: Can you develop new colors for us ?

A: Yes we can. You can provide us color samples, then we can develop the lab dips for your confirmation Within 7-10days.

4.Q: Can you change the thickness according to our demand?

A: Yes. Mostly the thickness of our artificial leather is 0.6mm-1.5mm,but we can develop different thickness for customers according to their usage. Such as

0.6mm,0.8mm,0.9mm,1.0mm,1.2mm,1.4mm,1.6mm.ect

5.Q: Can you change the backing fabric according to our demand?

A: Yes. we can develop different backing fabric for customers according to their usage.

6.Q: How about your lead time ?

A: About 15 to 30days upon receiving your deposit

EN

EN

AR

AR

CS

CS

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

MT

MT

TH

TH

FA

FA

AF

AF

MS

MS

GA

GA

HY

HY

AZ

AZ

BN

BN

LA

LA

MN

MN

KK

KK

UZ

UZ

KU

KU